Explosives vs. Propellant Base Rock Breaking Cartridges:

| Detonating explosives | Deflagration | |

|---|---|---|

| Description | Modern detonating commercial explosives are based on: 1) Ammonium Nitrate mixed with a fuel and cross-linked sensitizers with a gel forming polymer (pumpable explosives). 2) Ammonium Nitrate Diesel fuel mix (with a small % Aluminium). |

Deflagration is a reaction caused by a fast burning reaction. The reaction rate (burning rate) depends on the pressure increase. The higher the pressure the faster the burning rate. |

| Method of ignition | The explosive can only be ignited with a shock wave reaction achieved with a detonator. In some cases, a booster is added to enhance the detonation reaction. | A deflagrating mix is ignited by a hot flame from: 1. an electric match (fuse head). 2. or a pyrotechnic igniter from a shock tube igniter. |

| Detonation reaction | Detonation reactions are super-fast chemical reactions in an explosive mix and consist of a very high gas reaction that will form an ultra-high pressure wave. This pressure wave will create a shock wave that is defined as a detonation wave. | Deflagration is a reaction caused by a fast burning reaction. The reaction rate (burning rate) depends on the pressure. The higher the pressure the faster the burning rate. |

| Pressure | The pressure and speed of the detonation wave is extremely high. Pressure = 1 200 Giga Pascal (100 km meter sea water = 1 Giga Pascal, thus 1 200 Giga Pascal = 120 000 km sea water) |

The typical pressure created in a rock when a deflagrating reaction fully develops is 380 – 480 Mega Pascal. (1199 million Pascal x less that with explosives) |

| Reaction Speed | The reaction speed, defined as Velocity of Detonation (VOD) is between 3 000 to 6 000m/s for commercial explosives. | The reaction speed is between 300 – 500m/s (1000 m/s less) |

| Destruction of chemical bonds | Because of the high pressure and speed of the chemical reaction (detonation wave), it changes the material’s chemical bonds (atomic bonds). This breakdown of the chemical bonds on atomic level is the reason for destruction of surounding material when a detonation wave is passing through the material. The destruction of the material (in our case rock) depends on the characteristic of the material. Rock is a dense crystalline material and will disintegrate on atomic level when a detonation wave moves through the crystals. This continuous until the energy is absorbed and the detonation wave slows down to a shock wave and then to a sound wave. |

Because of the relative low reaction speed and pressures, there is no detonation wave formation. The chemicals reacts to the heat and, depending on the pressure, decomposes to form gasses as reaction products. Pressurized gasses in the drill hole forces the surrounding rock in the direction of the free face. When the shear stresses “pull” the rock out, stresses are released and the rock breaks on its natural boundaries. This results in a breaking method that can be determined by the size of the cartridge. Minimum dust formation will occur. |

| Gasses | Detonation reactions will result in the formation of unbalanced reaction products of which CO, NOx are the major role players. Volume of gas formed per 1.2m x 40mm dia, hole blasted: 2095.6L. |

The chemicals in the propellant base cartridge are mixed in a ratio with an oxidiser so that the reaction gasses wil produce a 2% Oxygen, (in lab conditions). The resulting gasses are: CO2, NO and H2O. Volume of gas created by 1 hole 1.2m deep 40mm dia. with 1 RBC Cartridge: 235.47L |

| Dust formation | The detonation reaction atomises the rock to a diameter of 100mm around the blast hole 40mm dia and 1.2m deep. This results in a dust mass of approximately 22.01kg per hole. | There is no detonation reaction and no dust will be formed. |

Comparison table on a 3,2 x 3,2 x 1,2m face

| Properties | Value of Explosives | Value Propellant Rock Breaking Cartridge |

|---|---|---|

| Energy Kcal/Kg | 718 | 911 |

| Energy MJ/Kg | 3 | 3.81 |

| Velocity of Detonation m/s | 3 000 | 450 |

| Kg Explosive / hole | 2.31 | 0.25 |

| Holes charged | 41 | 49 |

| Total Explosive / Round Kg | 94.83 | 12.5 |

| Energy / round MJ | 284.5 | 46.55 |

| Vol of Gas / round L | 85 919 | 11 538 |

| Vol of Gas/Hole L | 2 095.6 | 235.47 |

| Dust formation | 1976.6 Kg | <1 |

Advantages of the processes

1

No Shock wave formation during the rock breaking process.

2

Less toxic gas and dust. Safe to work in.

3

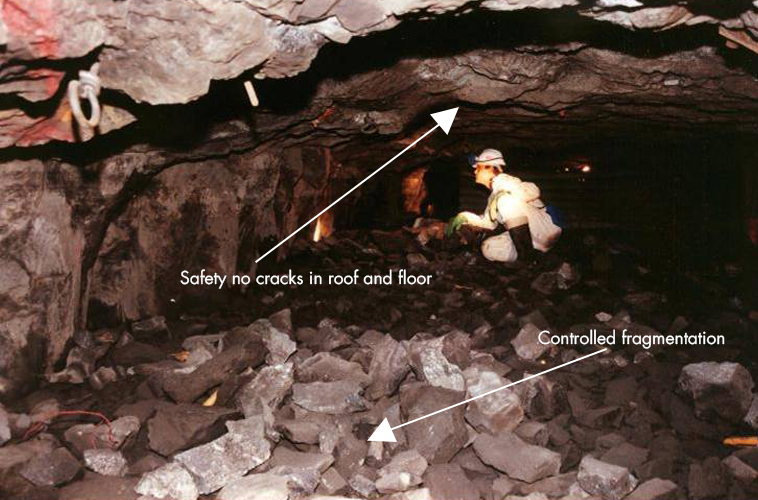

Safety: less stress and cracks in the roof.

4

No destruction of supports.

5

Easy to use (same drill pattern, same rules for explosives).

6

Low cost equipment - easy to maintain.

7

Electronic blast control with data capture and reporting.

8

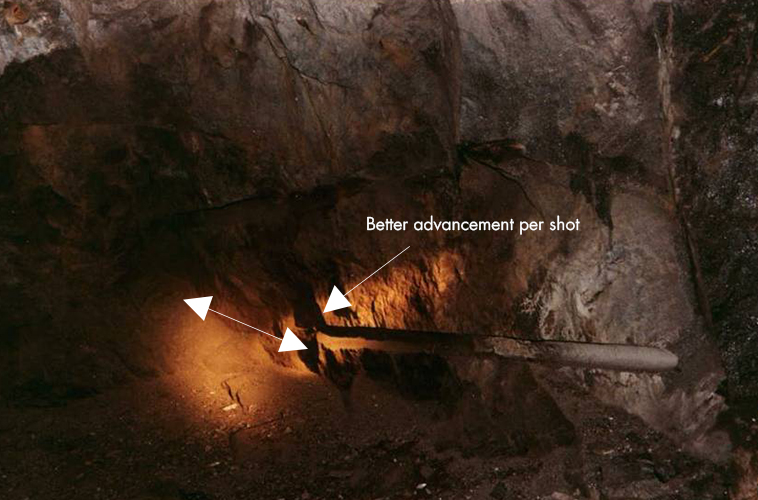

Continuous mining process possible, 2 -3 blast per 24 h cycle.

9

Only ore rich material to be transported to the process plant.

10

Process can be developed for automation.

11

Waste material to be used as back fill.

- Excellent fragmentation on stoping. Roof conditions improved once we passed the normal explosive rock breaking conditions. No secondary breakage in the roof or floor making the workplace very safe. The non detonating process from AVD Consulting doesn’t destroy the support which is a great improvement in safety.

- Clean breaking on stope face Amandelbult Platinum Mine

- 1,2m holes give over break in stope at Amandelbult platinum mine project