Stoping

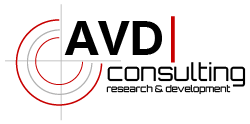

- Excellent fragmentation on stoping. Roof conditions improved once we passed the normal explosive rock breaking conditions. No secondary breakage in the roof or floor making the workplace very safe. The non detonating process from AVD Consulting doesn’t destroy the support which is a great improvement in safety.

- Clean breaking on stope face Amandelbult Platinum Mine

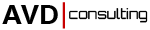

- 1,2m holes give over break in stope at Amandelbult platinum mine project

Mining development/Tunnelling

- The first under ground operation developing a 2x2m tunnel in the oldest gold mine in South Africa. This tunnel were developed while other mining operations was running. The crew was in a safe waiting place 30m from the blasting area with a return time of 10min after the blast. “Barrels” in the side wall are clearly visible (left side of the tunnel)

- Clean breaking of the rock on the side and roof wall is clearly visable. Recovery of the gold ore in solid fragmented rock resulted in super high grade recovery of gold. No ore was lost because of blasting damage. No secondary cracks in the side and roof wall are formed when using the AVD Consulting process. Deep level mining (2, 6 – 4km)

- Deep level mining require special methods and procedures. The AVD Consulting process was also applied in this project where more than 100m of 3, 2 x 3, 2 m development ends were developed. No seismicity was recorded during this operation. This methodology opened up new exciting mining methods

- Fragmentation of the rock were consistent resulting in high gold grade recovery This development was done in one of the leading Gold producers in the world at 2, 6 km deep level.

- Dust control: No dust and very limited reaction gases after a blast in a 6 x 6 m tunnel development end. Return time between 3 – 10 min

- Developing a 6 x 6m tunnel in soft rock structure. The tunnel was developed in a seismic sensitive area. Burden and spacings were calculated to optimise the breaking of the rock with the minimum number of Rock Breaking Cartridges. Each design was calculated to give measurements below the critical frequencies for historical building vibrations.

- Excelent roof and side wall conditions were acheved in the development of this 6 x 6m tunnel underneath a 200 year old historical building. The tunnel development was done with Deflagrating Rock Breaking Cartridges. A specific blast design was developed and patented.

- A development shaft for the development of the 6x6m tunnel

- Fragmentation of the rock from the 6x6m tunnel, is controlled for easy cleaning operations .